Skyler Rotate

Remote condition monitoring for your rotating assets. Skyler Rotate easily integrates IIoT into your facility to help your team get ahead of emergencies.

Skyler Rotate provides continuous monitoring for the most production-critical rotating equipment …

Motors

Pumps

Bearing Boxes

Gearboxes

Fans

… across many different industries

- Cement and Building Materials

- Metals

- Chemicals

- Plastics

- Water Treatment

- Power Generation

- Food & Beverage

- Glass

- Pulp & Paper

- Mining

- Pharma & Life Sciences

- Consumer Packaged Goods

- Healthcare

- Steel

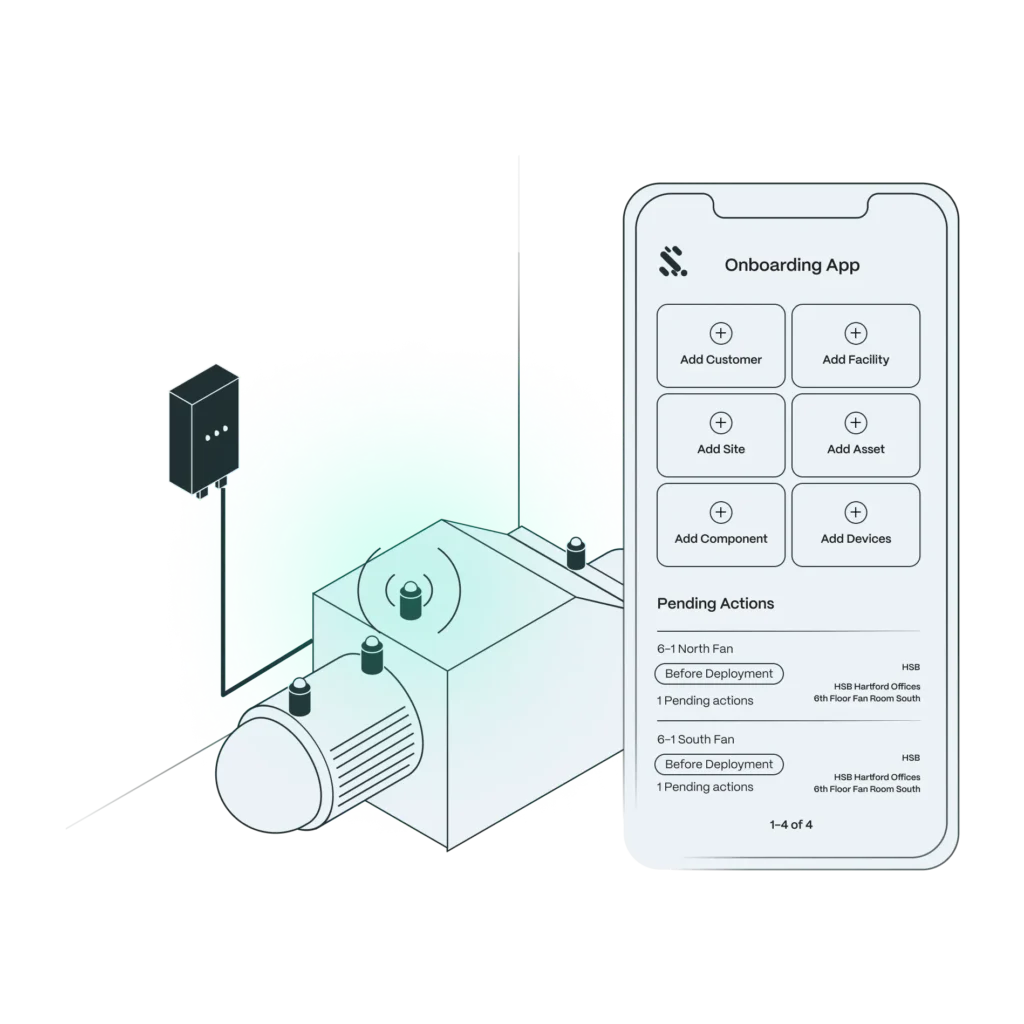

How it Works

Deploy

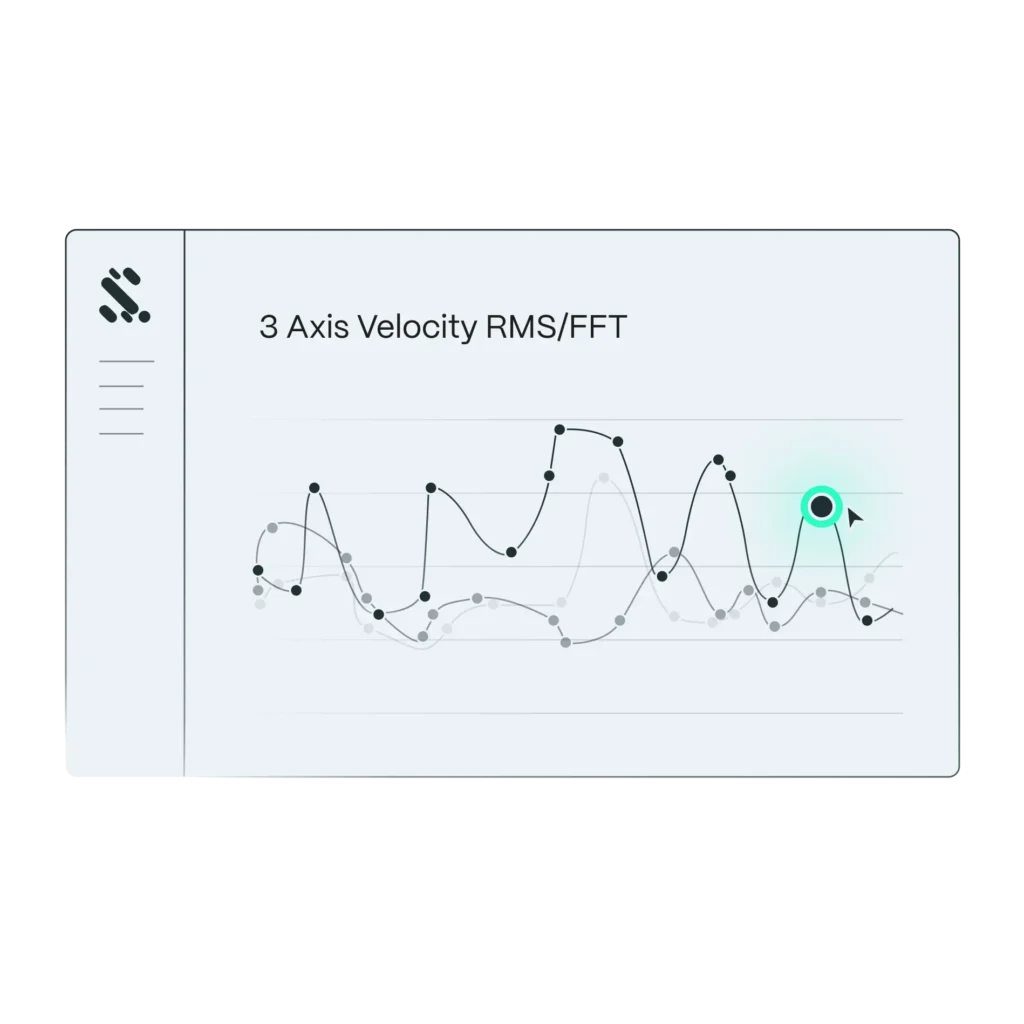

Monitor

Predict

Maintain

Detectable Faults

Air Gap Variation (Soft Foot)

Bearing Ball (Roller) Fault

Bearing Cage Fault

Bearing Inner Race Fault (BPFI)

Bearing Outer Race Fault (BPFO)

Lack of Bearing Lubrication

Journal Bearing Looseness

Cocked Bearing

Blade/Vane Pass

Journal Bearing Misalignment

Gear Tooth Wear

Gear Friction

Bent Shaft

Fan Eccentricity

Coupling Misalignment

Pulley Misalignment

Imbalance

Looseness

Eccentric Gears

Worn / Defective Belts

Worn / Eccentric Fan Sheave

Gear Misalignment

Cracked/Broken Gear Tooth

Motor Loose / Open Rotor Bars

Cracked / Broken Rotor Bars

Eccentric Rotor

Beat Frequency

Loose Stator Windings

Motor Status Eccentricity

Phase Problems (Loose Connector)

Resonance

Shaft Eccentricity

Structural Mechanical Looseness

Worn / Eccentric Motor Sheave

Unexpected breakdowns and costly emergency repairs

Eliminate unplanned downtime with predictive failure detection and proactive maintenance recommendations

Effectiveness of maintenance activities difficult to assess

Confirm the effectiveness of maintenance using asset health data and reduce operational risk

Skills gap and limited bandwidth of experts

Empower your reliability team to manage your entire fleet with actionable insights and maintenance recommendations

Asset data requires expert skills to interpret

Get actionable insights presented in intuitive dashboards and notifications so no expert knowledge is required, but detailed data is available when required

Talk to an Expert

Discover what’s possible for your business, talk to one of our experts.